An article to let you know about PVC ball valves

PVC ball valve function

Ball valve, a valve in which the opening and closing part (ball) is driven by the valve stem and rotates around the axis of the valve stem. It is mainly used to cut off or connect the medium in the pipeline. It can also be used for fluid adjustment and control. Among them, the hard-sealed V-shaped ball valve has a strong shear between the V-shaped core and the metal seat of the hard alloy. Shearing force is especially suitable for media containing fibers and tiny solid particles.

The multi-way ball valve on the pipeline can not only flexibly control the confluence, divergence, and flow direction switching of the medium, but also close any channel to connect the other two channels. This type of valve should generally be installed horizontally in the pipeline.

Ball valve classification: pneumatic ball valve, electric ball valve, manual ball valve.

Basic Information

Generally, the application of pvc ball valve should not exceed 45℃, and the medium is not suitable for organic solvents and strong oxidants. According to this situation, this type of ball valve is restricted to use fluids below 45°C and the pressure is less than 1.0mpa.

Compared with other valves, it has the following advantages.

1. Low fluid resistance

The ball valve is the one with the least fluid resistance among all valves, even the reduced diameter ball valve, its fluid resistance is quite small. The PVC ball valve is a new material ball valve product developed according to the needs of various corrosive pipeline fluids. Product advantages: light weight, strong corrosion resistance, compact and beautiful appearance, light weight and easy installation of the body, strong corrosion resistance, wide application range, hygienic and non-toxic materials, wear resistance, easy disassembly, simple maintenance .

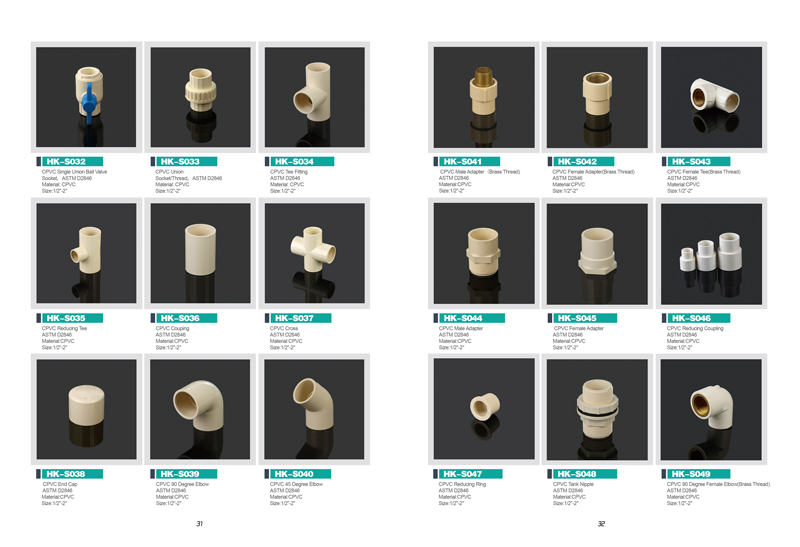

In addition to PVC plastic materials, plastic ball valves also include PPR, PVDF, PPH, CPVC, etc.

2. PVC ball valve has excellent corrosion resistance.

The sealing ring adopts F4. Excellent corrosion resistance and prolong service life. Flexible rotation and easy to use.

3. As an integral ball valve, the PVC ball valve has few leakage points, high strength, and the connection type ball valve is easy to assemble and disassemble.

The installation and use of the ball valve: When the flanges at both ends are connected with the pipeline, the bolts should be tightened evenly to prevent the flange from being deformed and causing leakage. Turn the handle clockwise to close, and vice versa to open. It can only be used for cut-off and flow-through, and flow adjustment is not suitable. Liquids containing hard particles can easily scratch the surface of the ball.

4.Strong function:

Intelligent type, proportional type, switch type everything, small size: the volume is only equivalent to about 35% of similar products.

5.Light and cheap people:

The weight is only about 30% of similar products, and the performance is reliable: the bearings and electrical components adopt imported famous brand products.

6.Beautiful and generous:

Aluminum alloy die-casting shell, fine and smooth, high strength and wear resistance: special copper alloy forged worm wheel, high strength, good wear resistance.

7.Safety guarantee:

1500v withstand voltage, special wire lock to lock the cable line is simple: single-phase power supply, external wiring is particularly simple.

8.Easy to use:

Oil-free and spot-inspected, waterproof and rust-proof, installed at any angle, protection device: double limit, overheat protection, overload protection.

9.Multiple speeds:

The total travel time is 5 to 60 seconds, meeting the requirements of different working conditions, special-grade wires: use heat-resistant flame-retardant wires, which are not aging when heated, and are safe and reliable.

technical parameter

Applicable fluid: water, air, oil, corrosive chemical liquid

For example: piping systems for pure water and raw drinking water, drainage and sewage piping systems, brine and seawater piping systems,

Many industries such as acid-base and chemical solution systems.

Body material: PVC

Sealing material: EPDM/PTFE

Transmission mode: 90º rotary electric drive

Actuator material: cast aluminum alloy/plastic shell

Protection device: overheat protection

Action time: 4-30 seconds

Nominal pressure: 1.0Mpa

Nominal diameter: DN15-200

Protection level: IP65

Fluid temperature: -15℃-60℃ (no freezing)

Ambient temperature: -25℃-55℃

Power consumption: 8VA-30VA

Installation method: installation at any angle (horizontal or inclined installation is best for prolonging life)

Power supply voltage: standard AC220V, optional DC24V, AC110V

Voltage tolerance: ±10%, DC tolerance ±1%

Connection method: internal thread, bonding, flange

Connection diameter: 1/2"-4"

What are the tips for repairing pvc ball valves

★ If the ball valve leaks because of the loose handle, you can clamp the handle with a vise, and then rotate it counterclockwise to tighten the handle. It should be noted that you need to be careful when tightening the handle, do not use too much force, otherwise it is easy to break the ball valve.

★ If the place where the pvc ball valve is connected to the water pipe is not tight, and there is no good seal and there is water leakage, you can wrap the raw material tape around the place where the water pipe is connected to the ball valve, and install the ball valve after winding, so that there will be no water leakage.

★ If the water leakage is caused by cracking or defect of the ball valve, the old ball valve needs to be disassembled, and then a new one should be installed.

It should be noted that the pvc ball valve needs to be operated correctly during disassembly, and the following small points should be done.

★ After closing the ball valve, it is necessary to release all the pressure in the ball valve before disassembly, otherwise it is prone to danger. Many people don't pay attention to this. The valve is immediately disassembled after it is closed. There is still a certain amount of pressure inside. This part of the pressure is not released and is not conducive to personal safety.

★ After the ball valve is disassembled and repaired, it needs to be installed in the opposite direction of the disassembly and tightened and fixed, otherwise there will be water leakage.

If you want the pvc ball valve to last longer, it is necessary to reduce the number of switches as much as possible. When there is a water leak, you need to repair it in time according to the three tips in the article, and restore normal use as soon as possible.

Post time: Jan-05-2022